- #ASME Y14.5 2009 DIMENSIONING AND TOLERANCING ISO#

- #ASME Y14.5 2009 DIMENSIONING AND TOLERANCING SERIES#

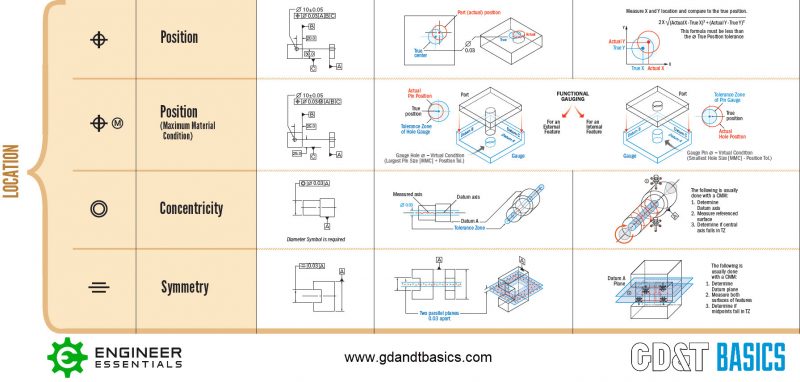

The Foreword of ASME Y14.5-2009 pointed out the increasing importance for design to more precisely state functional requirements through the use of geometric dimensioning and tolerancing (GD&T), and not to rely on the less definitive method of directly applied limit dimensions for form, orientation, location, and profile of part features.

The methods of application in model views are currently defined in ASME Y14.41, but the meanings of the tolerances are defined in this Standard. This is in part to ensure that this Standard is applicable to the use of dimensions and tolerances in models and model-based drawings. Based on guidance from the Y14 Committee, the material formerly in Section 1 has been reorganized into Sections 1 through 4, and the subsequent Sections have been renumbered.īecause of the widespread use of computer-aided design (CAD) and the industry transition toward reduced use of orthographic views for product definition, model views were added in many figures throughout the Standard. The objectives for this revision are to correct any inconsistencies in the previous edition, to determine actions based on deferred comments from the review of the previous edition’s draft, to include model-based applications in many of the example figures, and to address proposals submitted by the public or members of the Subcommittee.

#ASME Y14.5 2009 DIMENSIONING AND TOLERANCING ISO#

The primary differences between ASME and ISO standards related to GD&T are associated with the appearance and meaning of certain symbols.This issue is a revision of ASME Y14.5-2009, Dimensioning and Tolerancing. When necessary, differences between ASME Y14.5-2018 and related design and drafting standards are explained. Important differ- ences between ASME Y14.5-2018 and earlier editions, such as ASME Y14.5- 2009, are explained when necessary. It allows for com- munication of the functional design intent of parts and assemblies to everyone involved in N O T E This textbook focuses on the GD&T practices and theory provided in the ASME Y14.5-2018 Dimensioning and Tolerancing standard. GD&T is a design tool that offers a number of benefits in design and production. The purpose and relation- ship of a particular feature of a part dictates dimensioning and tolerancing practices. But, product design and manufacturing tools, equipment, materials, and pro- cesses are not perfect, and so end product geometry is not perfect. Benefits of GD&T A design concept, drawing, model, or document can represent the perfect size and shape of geometry. Example 1-4 shows some of the many published ISO standards related to dimensioning and tolerancing. ISO standards use multiple documents, many of which are grouped into several parts, to define engineering design and drafting practices and theory. For example, the ISO/TC 213 Dimensional and geometrical product specifications and veri- fication committee develops geometrical product specifications (GPS) standards for dimensioning and tolerancing. ISO technical committees are designated with the abbreviation ISO/TC followed by a number reference. ISO standards are prepared by ISO technical committees. ISO provides an extensive number of standards applicable to design and drafting. Example 1-3 shows some of the standards in the Y14 series.

#ASME Y14.5 2009 DIMENSIONING AND TOLERANCING SERIES#

The Y14 series includes standards related to drawing applications such as drawing formats, line conventions, dimensioning and tolerancing, and revisions, and specialty applications such as rep- resenting screw threads, gears and splines, and castings and forgings. ASME Y14.5-2018 There are many other standards in the ASME Y14 series.The following lists the editions of the Y14.5 standard dating to 1973: ASME revises the Y14.5 standard approximately every 10 years. The ANSI Y14.5-1973 standard was revised from the USASI Y14.5-1966 standard. The USASI Y14.5-1966 Dimen- sioning and Tolerancing for Engineering Drawings standard was based on earlier standards developed by different organizations, including the ASA Y14.5-1957 standard. Previous editions of the Y14.5 standard include standards designated by the American National Standards Institute (ANSI) and the organization that predated ANSI, the United States of America Standards Institute (USASI). As discussed earlier in this chapter, the ASME Y14.5 Dimensioning and Tolerancing standard specifies approved dimensioning and tolerancing practices for engineering drawings. Adoption of specific stan- dards is determined by a variety of operational and organizational considerations.

ASME and ISO standards are distributed and used worldwide.

8 Geometric Dimensioning and Tolerancing Copyright Goodheart-Willcox Co., Inc.

0 kommentar(er)

0 kommentar(er)